Employee

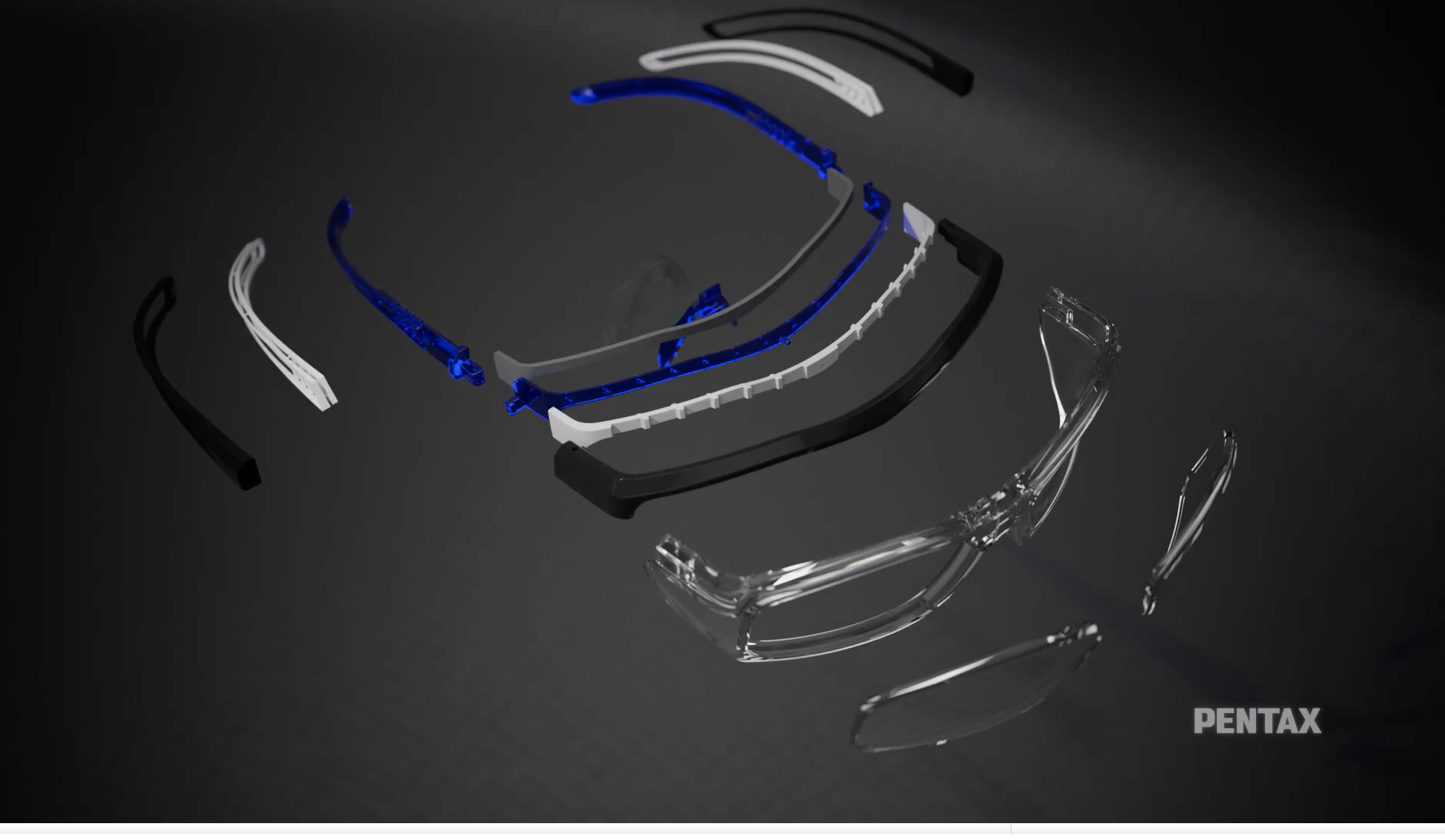

The Anatomy of Safety Eyewear

When you own a pair of safety eyewear, you should know each part of it and how each component works like anything meant to protect you. Our eyes are one of the most vulnerable parts of our bodies, so safety eyewear is necessary to keep them protected when working in industrial industries, playing sports, or even working behind desks. Here are the different types and components that make up the anatomy of safety eyewear.

The Anatomy of Safety Eyewear

You might be purchasing safety eyewear or already own a pair for your job, lounging at home looking at screens, or playing a sport. Whatever the reason, there are different types of safety eyewear to consider before purchasing to ensure you are getting the best protection for your situation.

Safety Glasses

Safety glasses can have nonprescription and prescription lenses typically made of polycarbonate material. The lenses paired with a durable and robust frame allows this eyewear to have the most options for wearers. Many safety glasses also come with side shields, gaskets, brow bars for protection, and possibly adjustable nose pads & temples for comfort and proper fitting. There are non-conductive styles; styles with removable side shields that double as your everyday pair; sunglass styles and much more.

OTG Safety Glasses

“Over-the-glasses” (OTG) are a less common option for those who wear prescription eyewear. As the name implies, they’re designed to be worn over other sets of glasses. Employees and employers are less inclined to utilize this because of discomfort and, lets be honest, style. They’re most often the option for certain hazardous areas in a workplace that are infrequently visited/utilized. In other words, if your workplace requires you to wear safety eyewear all day it’s best to invest in a proper pair of prescription safety eyewear.

Safety Goggles

Another common type of safety eyewear worn by many industries is safety goggles. Safety goggles are typically worn when a work environment requires protection against fine dust, hazardous fumes, or liquids. They can be made in nonprescription and with prescription lens inserts. There are three different types of goggles: non-vented, direct vented, or indirect vented. Non-vented safety goggles give users the most protection but sometimes have issues with fogging depending on your work environment. Direct vented goggles have several small holes around the top, bottom, and sides of goggles to allow airflow but still block anything bigger than 1.5 mm in diameter. These are the alternative options to help with fogging, but they don’t stop liquid from entering, so before purchasing, consider all possibilities. The final option is indirect ventilation which uses angled holes that face the rear and are often adjustable. This option protects from chemical and liquid splashes and helps prevent fog, but the ventilation is not as open as direct.

Safety Eyewear Features

Now that you know the most common types of safety eyewear, let’s get into the features of safety-specific eyewear as PPE.

Polycarbonate & Trivex Lenses

When it comes to prescription safety eyewear there are many options to consider but also standards to be mindful of. Impact resistance is the most critical difference when selecting prescription safety eyewear. All safety eyewear lenses must comply with the ANSI Z87.1 standards for high-impact resistance. Polycarbonate and Trivex lens materials are the only two materials recognized as high-impact materials by ANSI Z87.1 standards. Luckily, polycarbonate is the most common lens material in the eyeglass market. They are a superior quality material that does not shatter or break if dropped or hit at high speeds. They can also withstand extremely hot temperatures and block 100% of UV rays.

To create Polycarbonate lenses, tiny pellets of thermoplastic material melted down and injected into a high-pressure mold. They are thin and lightweight, can come in many tints and colors, and at SafeVision, our polycarbonate lenses have the option to add coatings such as anti-fog, anti-reflective, or anti-scratch. These reasons are why it is the most used material for safety eyewear.

At SafeVision we recommend our proprietary brand of Trivex material called Phoenix. They share all the benefits of polycarbonate including lightweight, optical clarity, 100% UV protection, and impact resistance. PLUS they’re far more chemical resistant than polycarbonate and, due to their manufacturing process, they are better suited for high wrap frames like sunglasses.

Side Shields

Side shields are added to eyewear to cover any large gaps to the sides of your eyes to prevent particles, dust, or liquids from entering your eyes from the sides. These are more common with styles that are more like standard everyday frames. Side shields are made of polycarbonate material which is, again, high impact rated. On the other hand, wraparound styles with a high curve tend to be designed with temples wide enough to cover the sides of your eyes. These styles are more similar to sporty sunglasses.

Gaskets and Nose or Temple Pads

Typically made from a foam or thermoplastic materials, gaskets are put on safety eyewear to create a firm seal on the wearer’s face. This seal keeps dust, wind, and other irritating particles out of the eyes. Nose and temple pads are made of similar materials and also enhance comfort and adjust to an individual’s features while playing sports or on the job, specifically in construction.

Ask a SafeVision Consultant

If you are looking to purchase or have purchased a pair of safety eyewear but aren’t sure what all the features help protect, reach out to one of our consultants at SafeVision! Our team is here to answer any of your questions about every piece and part of your prescription safety eyewear. Contact us today at safevision@hoya.com!