Eye Care Providers, Safety

ANSI Z87.1 Standards For Prescription Safety Eyewear

What is the difference between standard prescription eyewear and safety prescription eyewear? First and foremost, safety eyewear must meet a higher standard of impact resistance. OSHA, the Occupational Safety and Health Administration, is a government body that oversees safety practices in the workplace for American businesses. With regards to safety eyewear, OSHA defers to the American National Standards Institute (ANSI). ANSI is a non-profit organization with representatives from other standards organizations, government agencies, consumer groups, companies and other experts. ANSI Z87.1 standards focus on face and eye protection.

Impact Resistance

In terms of safety eyewear, impact resistance is the most important difference when selecting prescription safety eyewear vs. non-safety eyewear, sometimes called “dresswear” by eye care professionals. For impact resistance there are two key designations:

Basic impact: lenses tested separately (not mounted in a frame). This test involves a one-inch diameter steel ball dropping from a height of 50 inches. Lenses that crack, chip, or break do not pass. All safety lenses must have this test performed.

High impact: frame and lenses are tested together as a complete device. For this test, a quarter inch diameter steel ball shoots out at a speed of 150 feet per second. Here again, the lenses only pass if they do not crack, chip, or break. This is the high velocity test. Furthermore, the lenses cannot become dislodged from the frames.

Additionally, prescription lenses tend to be thicker than those used for non-prescription safety eyewear which means they’ll generally be more robust even when the same lens materials is used.

At SafeVision, we test ALL of our safety eyewear to meet high impact standards.

Easy To Find Markings

But how can you tell whether or not your prescription safety eyewear has been tested to these standards? The short answer: markings on the frame and lenses themselves indicate the type of testing that a pair of safety eyewear has undergone and passed per ANSI standards.

- Z87 = basic impact rating

- Z87+ = high-velocity impact rating

However, PRESCRIPTION safety eyewear receives a different set of markings:

- Z87-2 = basic impact rating

- Z87-2+ = high-velocity impact rating

Look at the front of the safety frame and the temples to find these markings. They will include the manufacturer/brand name or abbreviation plus the frame measurements.

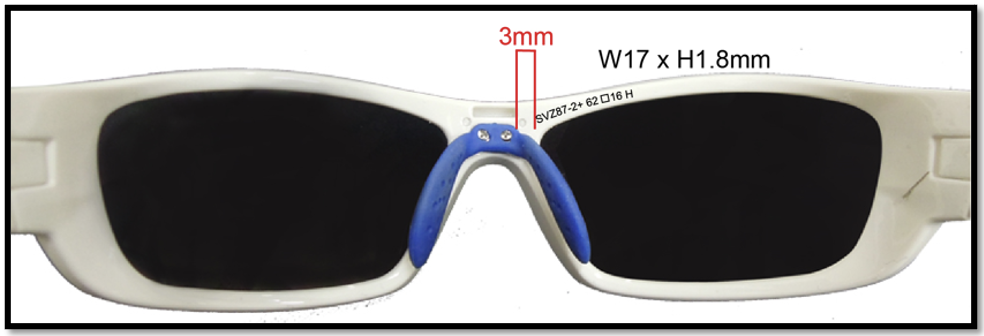

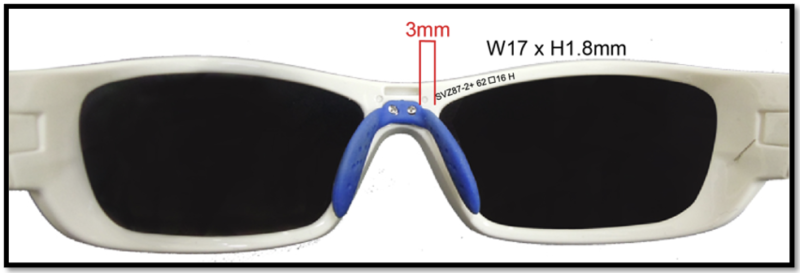

Let’s look at an example. Here is the front and left temple of our SVNY frame:

You’ll notice the SafeVision brand abbreviated as SV than the high impact/velocity marking for prescription eyewear Z87-2+ and then the measurements 62□16 which refer to the width of the lens = 62mm and the distance between the two lenses = 16mm.

Our SVNY frame also features the letter H which denotes frames designed for smaller heads. Another marking designation set forth by ANSI Z87.1 standards.

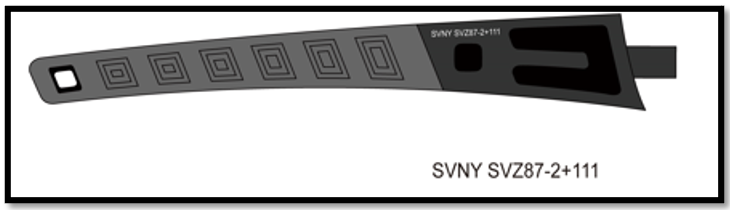

The Left Temple

When we look at the left temple, we’ll also find the name of the frame style, which in this case is SVNY. Also, the SV for SafeVision and, again, Z87-2+ for high impact/velocity and then 111 which is the temple length = 111mm.

Additionally, the prescription lenses themselves will receive a small engraving that features the manufacturer’s marking. In our case that may be either SV for SafeVision or HO for HOYA. As a division of HOYA we benefit from the technology and expertise offered by one of the world’s most prominent prescription eyewear manufacturers. A very important distinction is the use of the + symbol with the lens engraving. If this + symbol is not engraved on the lenses then they’re not rated for impact!

So, when you’re looking for a pair of prescription safety eyewear be sure to check for the Z87-2+ on the frame first and ask the eye care provider if their lenses will also feature the + engraving for high impact. REMEMBER high velocity/impact rated eyewear is tested together so it’s always best to find a company like SafeVision which sources its own frames and has its own dedicated lab to do so.

Other Symbols You’ll Find On Safety Eyewear

Here are a few additional symbols that you may find on safety eyewear:

- H indicates a product designed for smaller head sizes. (like or SVNY frame)

- V indicates photochromic lenses – also known as “variable tint” or “indoor-outdoor” lenses. (we offer some of the optical industries best photochromic lenses)

- S indicates a special lens tint. (SafeVision has a variety of lens tints to choose from)

- X indicates eyewear has passed the fog test and can resist fogging (our state of the art lab can coat nearly any lens material with our anti-fog treatment)

- D3 indicates splash and droplet protection.

- D4 indicates protection from dust particles.

- D5 indicates protection from fine

- For D3, D4 & D5, our new GT20 goggle, passes for all three levels of protection.

As you can see there are a variety of safety hazards that ANSI designed testing methodologies and criteria for. That’s why we highly recommend speaking with a SafeVision representative who can help determine what type of lenses and frames are best suited to keep your vision safe.

Work With SafeVision

Eye protection is no joke. Every day, industries across the country have workers experience eye injuries, of which 90% are preventable with the proper safety eyewear. That’s why we also offer corporate safety eyewear programs to help any organization source quality prescription safety eyewear that meet ANSI Z87.1 standards and also find local eyecare providers from within our nationwide network of partners. Whether you have a single location, or a massive work force spread across the country, SafeVision can help outfit them with prescription safety eyewear!

Learn More About SafeVision’s Safety Eyewear